Product Description

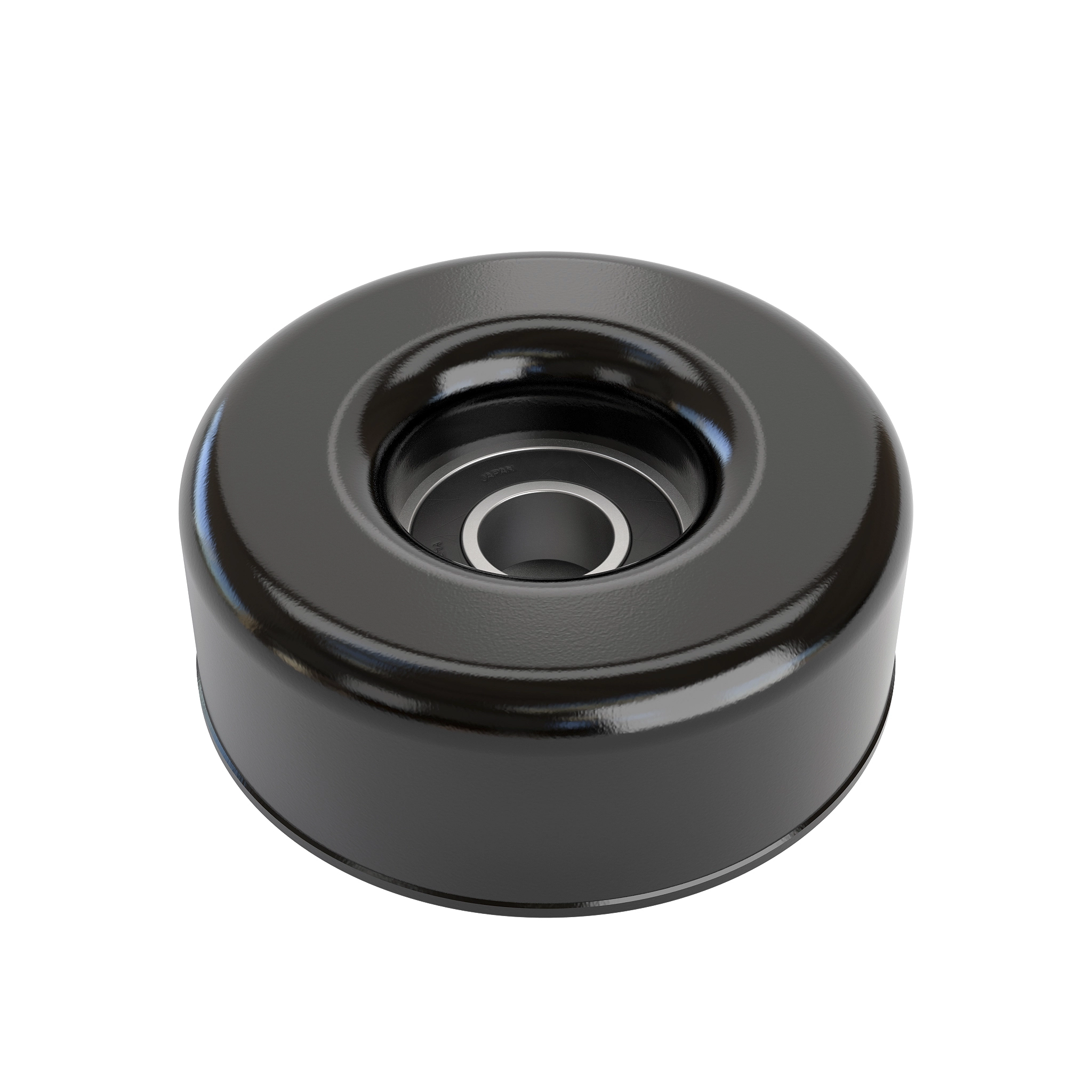

High Precision Positioning Transmission Parts Timing Belt Idler Pulleys

Synchronous belt pulley transmission is composed of an annular belt with equidistant teeth on the inner peripheral surface and a belt pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth slots of the belt pulley to transmit motion and power. It is a new belt transmission that integrates the respective advantages of belt transmission, chain transmission and gear transmission.

Product Description

| Product | standard timing belt pulley & idler pulley |

| Customized | OEM, drawings or samples customized |

| Teeth type | Normal Torque Drive Type:MXL,XL,L,H,XH,XXH High Torque Drive Type:S2M,S3M,S5M,S8M,HTD2M,HTD3M,HTD5M,HTD8M,P2M,P3M,P5M,P8M High Precision Position Drive Type:2GT,3GT,5GT,8YU Light Load Drive Type:T5,T10,T20 Heavy Load Drive Type:AT5,AT10,AT20 |

| Basic shape | Type A,Type B,Type D,Type E,Type F,Type K |

| Adaption | Adapt to 1/4 inch,5/16 inch,1/2 inch, 3/8inch, 2/25inch, 1/5inch belt |

| surface treatment | Natural color anodizing,Black anodizing,Hard anodizing,Ni-plating,Blackening |

| Material | 6061(aluminum),S45C(45# steel),SUS304(Stainless steel) |

| Bore | Pilot bore, Taper bore and Customized bore. |

| Tolerance Control | Outer diameter ±0.005mm Length dimension ±0.05mm |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN Class 4, ISO/GB Classs 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15Tons |

| testing equipment | projecting apparatus,salt spray test,durometer,and coating thickness tester,2D projector |

| producing equipment | CNC machine,automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Application industry | Robot industry,Medical industry,Making machine industry,Automation industry,3C industry equipment,Packaging industry,UAV industry,New energy industry. |

Company Profile

Packaging & Shipping

FAQ

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Forging |

| Material: | Stainless Steel |

| Surface Treatment: | Polishing |

| Application: | Machinery Parts |

| Samples: |

US$ 13/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do idler pulleys contribute to the functioning of HVAC and conveyor systems?

Idler pulleys play a crucial role in the functioning of HVAC (Heating, Ventilation, and Air Conditioning) and conveyor systems. Here’s a detailed explanation of how idler pulleys contribute to the operation of these systems:

HVAC Systems:

In HVAC systems, idler pulleys are primarily used for power transmission and belt tensioning. Here are the key ways in which idler pulleys contribute to the functioning of HVAC systems:

1. Belt Routing and Tensioning:

Idler pulleys guide and support the belts used in HVAC systems, ensuring proper routing and tensioning. They help keep the belts in alignment with the driving and driven pulleys, preventing slippage and ensuring efficient power transmission. Idler pulleys maintain the necessary tension in the belts, which is crucial for optimal HVAC system operation.

2. Load Distribution:

Idler pulleys assist in distributing the load evenly across the HVAC system. By supporting the movement of belts, they help distribute the load and minimize stress on individual components. Proper load distribution ensures balanced wear and tear, prolonging the lifespan of the system.

3. Noise and Vibration Reduction:

Idler pulleys contribute to reducing noise and vibration in HVAC systems. They help dampen vibrations caused by belt operation, resulting in quieter and smoother system performance. Reduced noise and vibration levels enhance the comfort and usability of the HVAC system.

4. System Efficiency:

Efficient idler pulley operation improves the overall efficiency of HVAC systems. Well-designed idler pulleys with low friction and proper tensioning minimize power losses, ensuring optimal energy consumption. By reducing inefficiencies and maximizing energy conservation, idler pulleys contribute to improved HVAC system performance.

Conveyor Systems:

In conveyor systems, idler pulleys are essential for belt support, tensioning, and guiding. Here’s how idler pulleys contribute to the functioning of conveyor systems:

1. Belt Support:

Idler pulleys provide support to the conveyor belt, preventing sagging and maintaining its shape. They are strategically positioned along the belt path to support the weight of the conveyed material, ensuring smooth and reliable transportation. Proper belt support is crucial for preventing belt damage and ensuring efficient material handling.

2. Tensioning:

Idler pulleys are used for belt tensioning in conveyor systems. They help maintain the appropriate tension in the conveyor belt, ensuring proper engagement with the drive pulley and preventing slippage. Proper belt tensioning is critical for efficient power transmission and preventing material spillage or jamming.

3. Belt Guiding and Tracking:

Idler pulleys guide and track the conveyor belt, ensuring it stays aligned and centered. They are designed with grooves or cylindrical surfaces that match the shape of the conveyor belt, providing guidance and preventing lateral movement. By maintaining proper belt tracking, idler pulleys minimize belt misalignment, reducing the risk of damage and improving overall conveyor system performance.

4. Load Distribution:

Idler pulleys contribute to even load distribution in conveyor systems. By supporting the belt and load, they help distribute the weight evenly across the system, minimizing stress on individual components. Proper load distribution ensures reliable and efficient operation, preventing premature wear and component failure.

5. System Reliability:

Reliable idler pulley operation is crucial for the overall reliability of conveyor systems. Idler pulleys that are correctly sized, well-maintained, and properly lubricated contribute to the smooth and continuous operation of the system. They help minimize downtime, reduce the risk of belt slippage or jamming, and ensure the efficient movement of materials.

Overall, idler pulleys are essential components for the functioning of HVAC and conveyor systems. Their role in belt routing, tensioning, load distribution, noise reduction, system efficiency, and reliability makes them integral to the smooth operation and performance of these systems.

What role do idler pulleys play in maintaining proper belt alignment?

Idler pulleys play a crucial role in maintaining proper belt alignment in mechanical systems. Here’s a detailed explanation of the role idler pulleys play in maintaining proper belt alignment:

Proper belt alignment refers to the correct positioning of the belt along the pulleys in a system. It ensures that the belt remains centered on the pulleys and follows its intended path without deviating or slipping off. Belt misalignment can lead to a range of issues, including increased friction, wear, noise, and reduced power transmission efficiency. Idler pulleys help address these alignment challenges and contribute to the smooth operation of the system.

1. Belt Tracking:

Idler pulleys guide the belt and help maintain its tracking along the pulleys. They are strategically positioned to ensure that the belt remains in the desired position and follows the correct path. By providing a reference point and support, idler pulleys prevent the belt from wandering or shifting laterally, which could otherwise cause misalignment.

2. Tension Adjustment:

Idler pulleys can be used to adjust and maintain the tension in the belt, which is crucial for proper alignment. By adding or removing idler pulleys or adjusting their position, the tension in the belt can be controlled. Proper tension ensures that the belt remains engaged with the pulleys and does not slack or become too tight, both of which can lead to misalignment.

3. Belt Support:

Idler pulleys provide support to the belt, helping to prevent sagging or excessive vibration. They act as additional contact points along the belt’s path and distribute the load, ensuring that the belt remains in its intended position. This support helps maintain the alignment of the belt, especially in applications where the belt spans long distances or encounters varying loads.

4. Load Distribution:

Idler pulleys contribute to load distribution across the belt. By introducing additional pulleys strategically, the load on the belt can be divided, reducing stress on individual components. This helps to minimize the risk of belt misalignment due to uneven loading or excessive strain. By distributing the load, idler pulleys promote uniform wear and ensure the longevity of the belt.

5. Vibration and Noise Reduction:

Idler pulleys play a role in reducing vibration and noise in mechanical systems. Misaligned belts can cause excessive vibration and noise due to uneven forces and increased friction. By maintaining proper alignment, idler pulleys help minimize these issues, resulting in quieter operation and increased system stability.

Overall, idler pulleys are essential components in maintaining proper belt alignment. Their role in guiding the belt, adjusting tension, providing support, distributing load, and reducing vibration ensures that the belt remains properly aligned, leading to improved efficiency, reduced wear, and extended belt life in mechanical systems.

In which machinery and systems are idler pulleys commonly used?

Idler pulleys find wide applications in various machinery and systems where belt-driven power transmission is employed. Here are some common examples of machinery and systems where idler pulleys are commonly used:

1. Automotive Engines: Idler pulleys are utilized in automotive engines to guide and maintain tension in the accessory belts that drive components such as the alternator, water pump, power steering pump, and air conditioning compressor.

2. Conveyor Systems: Conveyor systems in industries like manufacturing, mining, and logistics use idler pulleys to support and guide the conveyor belts, ensuring smooth movement of materials along the desired path.

3. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often incorporate idler pulleys in the belt drive arrangements to maintain proper tension and alignment of belts driving components like fans, blowers, and compressors.

4. Agricultural Machinery: Various agricultural equipment, such as combines, tractors, and harvesters, employ idler pulleys to guide and tension belts that drive components like belts for power take-off (PTO) systems, augers, and conveyors.

5. Printers and Copiers: Idler pulleys are used in printing and copying machines to guide and tension the belts that drive paper feed mechanisms, rollers, and other components involved in the printing process.

6. Exercise Equipment: Many types of exercise equipment, including treadmills, stationary bikes, and rowing machines, incorporate idler pulleys in their belt drive systems to guide and tension the belts that provide resistance or transmit power.

7. Industrial Machinery: Idler pulleys are commonly found in various industrial machinery applications, such as woodworking machines, textile machinery, packaging equipment, and printing presses, where belt drives are used for power transmission.

8. Power Tools: Belt-driven power tools, such as table saws, drill presses, and band saws, often utilize idler pulleys to redirect the belt path and maintain tension for efficient power transfer.

These are just a few examples, and idler pulleys can be found in a wide range of machinery and systems where belt-driven power transmission is employed. The specific design and size of idler pulleys may vary depending on the application and load requirements of the system.

editor by CX

2024-04-22