Product Description

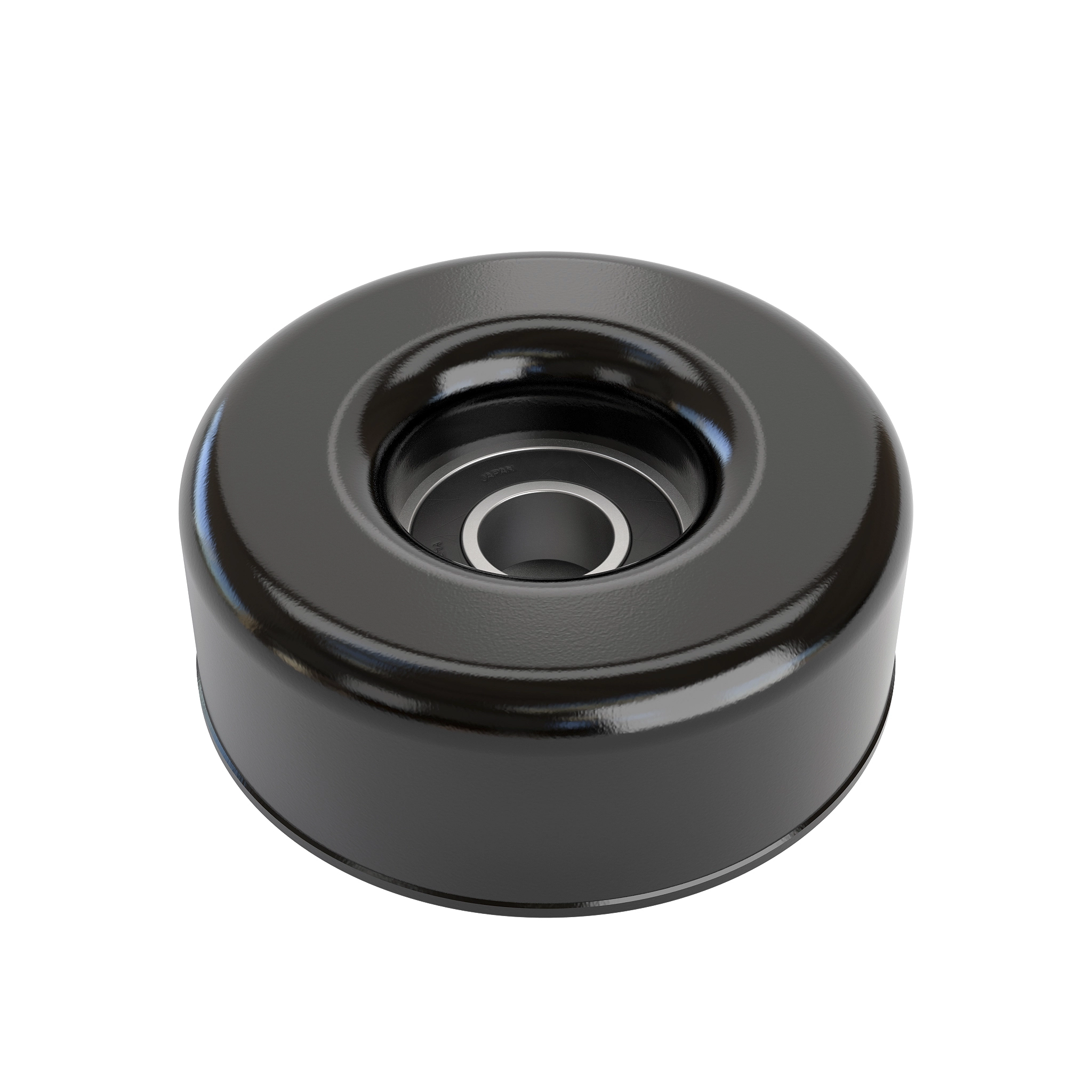

Welding Idler Pulley of Oil Rig for Mining Heavy Equipment

Product Description

Container crane pulley block,

With high bearing capacity, high wear resistance and long service life

Sheave features:

1) Material: Q235B, Q345B, 35#, 45#, 60#, SSW-QR1, S45C

2) Groove surface quench: HRC45-55

3) Groove surface quench depth: 2mm-2.5mm

4) groove MT after heat treatment and welding line UT and MT

5) Max processing diameter: 2, 000mm

6) Short production cycle

It is used for crane equipment, port equipment, oil drilling rig and so on.

Detailed Photos

Our Advantages

Application

| Other Products |

Company Profile

Factory introduction

HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. is a high-tech enterprise registered in HangZhou City of ZheJiang Province, which is mainly engaged in the design and manufacture of spare parts for metallurgy equipment, hoisting machinery, oil drilling rigs, and heavy decelerator boxes.

Our company boasts a professional team who is full of vitality, with high efficiency, and industry minded. Our R&D technicians are highly skilled with rich experience, and possess strong design and development capabilities. There are 2 experts in our company who enjoy the state special allowance. We have carried out broad cooperation with renowned factories and design institutes both at home and abroad.

With advanced design, outstanding manufacturing crafts and vigorous management, the whole manufacturing process of our company is conducted by strictly implementing strict quality management system. Our products are widely used by a great number of steel plants in China and exported overseas, where they have received high praise from our customers.

By following the enterprise philosophy of innovation, quality and creating value for the clients, our company is constantly bringing in advanced technologies from home and abroad. We are committed to taking the enhancement of product quality, safety and reliability as our responsibility and striving for providing high quality products and perfect services to the clients.

HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. Warmly welcomes you to be our distinguished clients and friends.

Customer communication

Certifications

| Packaging & Shipping |

FAQ

Q: What information should I provide if I want to order the products?

1) Product information: Quantity, specification

2) Delivery time required.

3) Shipping information: Company name, address, phone number, destination seaport/air port.

4) Forwarder’s contact details if there is any in China.

Q: How about your payment terms?

A: 30% -50%deposit, with the balance before delivery, we accept T/T and L/C at sight.

Q: Can I use our own logo?

A: Yes, we can produce by using your own logo if you need.

Q: How about sample & MOQ policy?

A: Welcome sample order. MOQ can be 1 set.

Q: What is your lead time for your goods?

A: Normally 30 days after confirmed order,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Lifting |

|---|---|

| Material: | Steel |

| Lifting Capacity: | <1T |

| Fixed Form: | Welding Type |

| Shape: | Round |

| Certification: | ISO 9001 |

| Customization: |

Available

| Customized Request |

|---|

What is the significance of proper alignment and tensioning in idler pulley systems?

Proper alignment and tensioning in idler pulley systems are of utmost significance for their optimal performance and longevity. Here’s a detailed explanation of the significance of proper alignment and tensioning:

1. Efficient Power Transmission:

Proper alignment and tensioning ensure efficient power transmission in idler pulley systems. When the belts or chains are correctly aligned with the pulleys, there is maximum contact and engagement, minimizing slippage and power loss. Optimal tensioning ensures that the belts or chains are appropriately tensioned, allowing for efficient transfer of power from the driving pulley to the driven pulley. Efficient power transmission improves the overall performance and productivity of the system.

2. Reduced Wear and Tear:

Proper alignment and tensioning help reduce wear and tear on belts, chains, pulleys, and other system components. Misalignment or inadequate tension can cause excessive stress, uneven loading, and premature wear. Misaligned belts or chains can rub against pulleys or adjacent components, leading to accelerated wear and potential damage. By ensuring proper alignment and tensioning, the system components experience minimal friction, resulting in reduced wear and extended service life.

3. Noise Reduction:

Proper alignment and tensioning contribute to noise reduction in idler pulley systems. Misaligned belts or chains can generate noise due to rubbing or vibration. Inadequate tensioning can cause belts or chains to slip or vibrate, resulting in noise generation. By aligning the belts or chains accurately and applying the correct tension, the system operates smoothly and quietly, enhancing the comfort and usability of the equipment.

4. System Stability and Reliability:

Proper alignment and tensioning promote system stability and reliability. When belts or chains are aligned correctly, they remain securely engaged with the pulleys, minimizing the risk of disengagement or derailing. Optimal tensioning ensures that the belts or chains maintain consistent tension, preventing slack or excessive tightness that could compromise system operation. A stable and reliable idler pulley system is crucial for maintaining continuous and trouble-free operation in various applications.

5. Extended Component Lifespan:

Proper alignment and tensioning help extend the lifespan of system components, including belts, chains, pulleys, and bearings. Misalignment and improper tensioning exert additional stress on these components, leading to accelerated wear and potential failure. By maintaining proper alignment and tension, the load is evenly distributed, reducing the strain on individual components and promoting their durability. Extended component lifespan translates to reduced maintenance costs and increased overall system productivity.

6. Safety:

Proper alignment and tensioning contribute to the safety of idler pulley systems. Misaligned belts or chains can pose safety hazards by coming into contact with surrounding equipment or personnel. Inadequate tensioning can result in sudden belt or chain disengagement, causing unexpected machine shutdowns or potential injuries. By ensuring proper alignment and tensioning, the risk of accidents or equipment damage is minimized, enhancing the safety of the working environment.

Overall, proper alignment and tensioning are vital for the efficient operation, reliability, longevity, noise reduction, and safety of idler pulley systems. Regular inspection, adjustment, and maintenance of alignment and tensioning parameters are essential to optimize system performance and maintain the integrity of the components involved.

What role do idler pulleys play in maintaining proper belt alignment?

Idler pulleys play a crucial role in maintaining proper belt alignment in mechanical systems. Here’s a detailed explanation of the role idler pulleys play in maintaining proper belt alignment:

Proper belt alignment refers to the correct positioning of the belt along the pulleys in a system. It ensures that the belt remains centered on the pulleys and follows its intended path without deviating or slipping off. Belt misalignment can lead to a range of issues, including increased friction, wear, noise, and reduced power transmission efficiency. Idler pulleys help address these alignment challenges and contribute to the smooth operation of the system.

1. Belt Tracking:

Idler pulleys guide the belt and help maintain its tracking along the pulleys. They are strategically positioned to ensure that the belt remains in the desired position and follows the correct path. By providing a reference point and support, idler pulleys prevent the belt from wandering or shifting laterally, which could otherwise cause misalignment.

2. Tension Adjustment:

Idler pulleys can be used to adjust and maintain the tension in the belt, which is crucial for proper alignment. By adding or removing idler pulleys or adjusting their position, the tension in the belt can be controlled. Proper tension ensures that the belt remains engaged with the pulleys and does not slack or become too tight, both of which can lead to misalignment.

3. Belt Support:

Idler pulleys provide support to the belt, helping to prevent sagging or excessive vibration. They act as additional contact points along the belt’s path and distribute the load, ensuring that the belt remains in its intended position. This support helps maintain the alignment of the belt, especially in applications where the belt spans long distances or encounters varying loads.

4. Load Distribution:

Idler pulleys contribute to load distribution across the belt. By introducing additional pulleys strategically, the load on the belt can be divided, reducing stress on individual components. This helps to minimize the risk of belt misalignment due to uneven loading or excessive strain. By distributing the load, idler pulleys promote uniform wear and ensure the longevity of the belt.

5. Vibration and Noise Reduction:

Idler pulleys play a role in reducing vibration and noise in mechanical systems. Misaligned belts can cause excessive vibration and noise due to uneven forces and increased friction. By maintaining proper alignment, idler pulleys help minimize these issues, resulting in quieter operation and increased system stability.

Overall, idler pulleys are essential components in maintaining proper belt alignment. Their role in guiding the belt, adjusting tension, providing support, distributing load, and reducing vibration ensures that the belt remains properly aligned, leading to improved efficiency, reduced wear, and extended belt life in mechanical systems.

In which machinery and systems are idler pulleys commonly used?

Idler pulleys find wide applications in various machinery and systems where belt-driven power transmission is employed. Here are some common examples of machinery and systems where idler pulleys are commonly used:

1. Automotive Engines: Idler pulleys are utilized in automotive engines to guide and maintain tension in the accessory belts that drive components such as the alternator, water pump, power steering pump, and air conditioning compressor.

2. Conveyor Systems: Conveyor systems in industries like manufacturing, mining, and logistics use idler pulleys to support and guide the conveyor belts, ensuring smooth movement of materials along the desired path.

3. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often incorporate idler pulleys in the belt drive arrangements to maintain proper tension and alignment of belts driving components like fans, blowers, and compressors.

4. Agricultural Machinery: Various agricultural equipment, such as combines, tractors, and harvesters, employ idler pulleys to guide and tension belts that drive components like belts for power take-off (PTO) systems, augers, and conveyors.

5. Printers and Copiers: Idler pulleys are used in printing and copying machines to guide and tension the belts that drive paper feed mechanisms, rollers, and other components involved in the printing process.

6. Exercise Equipment: Many types of exercise equipment, including treadmills, stationary bikes, and rowing machines, incorporate idler pulleys in their belt drive systems to guide and tension the belts that provide resistance or transmit power.

7. Industrial Machinery: Idler pulleys are commonly found in various industrial machinery applications, such as woodworking machines, textile machinery, packaging equipment, and printing presses, where belt drives are used for power transmission.

8. Power Tools: Belt-driven power tools, such as table saws, drill presses, and band saws, often utilize idler pulleys to redirect the belt path and maintain tension for efficient power transfer.

These are just a few examples, and idler pulleys can be found in a wide range of machinery and systems where belt-driven power transmission is employed. The specific design and size of idler pulleys may vary depending on the application and load requirements of the system.

editor by CX

2024-04-10