Product Description

Product Description

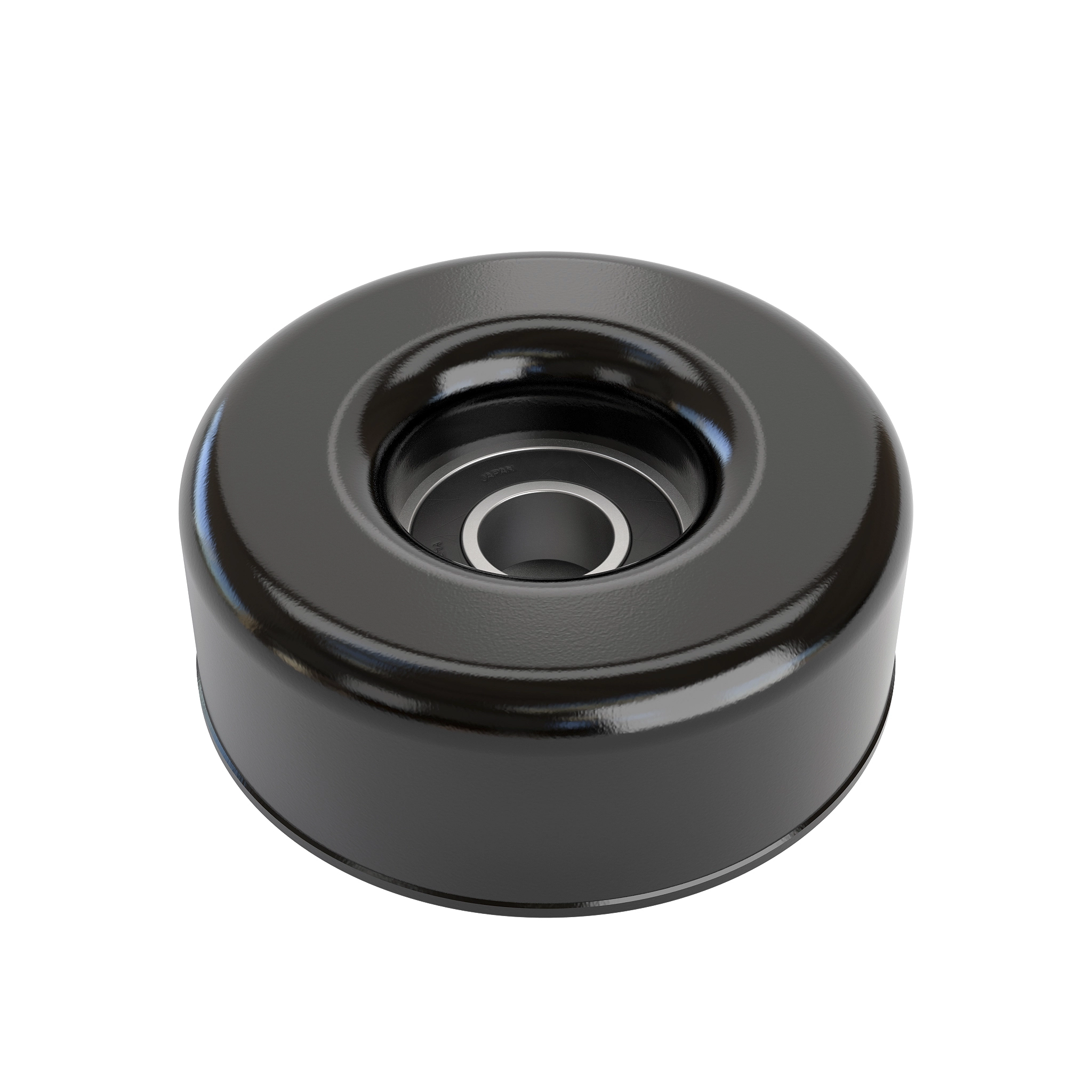

Original Industrial ISDE Diesel Engine Spare Parts 4991240 Idler Pulley For Cummins

| Product Name | Idler Pulley |

| Part Number | 4991240 |

| Packing | Original Packing |

| Application | Construction machinery diesel engine part |

| After-Service | Strict test before shipment/fast delivery |

Our Service

ZheJiang CHINAMFG Science and Technology Co., Ltd. (Hongjun) is the chinese leading one-stop supplier of spare parts for heavy machinery, marine and heavy trucks! Based on its extensive network , CHINAMFG is able to provide the most satisfying one-stop service for its customers!

CHINAMFG supply spare parts for

1.Wheelloader,excavator,grader,roller,bulldozer

2.Truck crance

3.Mining truck

4.Concrete pump

We can supply spare parts for all bellowing Cumming models:

B Series:

B3.3(Tier 4 Interim) B3.3(Tier 2) B3.3(Tier 3) B3.9CS4

B3.9 B4.5(Stage V) B5.9(Tier 2) B5.9CS4

B6.2 B6.7(Stage V) B6.7CS4 B7

B Series (Tier 2) 4B3.3

C Series:

C8.3(Tier 2)

D Series:

D4.5 D6.7

F Series:

F2.5 F3.8(Stage V)

I Series:

ISM11

K Series:

K19

L Series:

L8.9 L9 (Stage V) L9 Plus L9.3

L9CS4

M Series:

M11 M12 M14CS4 M15

M15 Plus

N Series:

N14 Plus NT

Q Series:

QSX11.9 (Tier 4 Interim) QSX15 (Tier 4 Final/Sate IV) QSX15 (Tier 4 Interim)

QSG12 (Tier 4 Final/Stage IV) QSLP (Tier 4 Final/Stage IV) QSLP (Tier 4 Interim)

QSB3.3 (Tier 4 Interim) QSB3.3 (Tier 3) QSB6.7 (Tier 4 Final/Stage IV)

QSB4.5 (Tier 4 Final/Stage IV) QSB6.7 (Tier 4 Interim) QSB4.5 (Tier 4 Interim)

QSB4.5 ( Tier 3) QSB4.5 QSB5.9

QSB6.7 (Tier 3) QSB6.7 QSB7

QSF3.8 (Tier 4 Final/State IV) QSF2.8 (Tier 4 Final/Stage IV) QSK19 (Tier 3)

QSK (Tier 3) QSL (Tier 3) QSL (Tier 2)

QSL9 (Tier 4 Interim) QSL9.3 QSL9 (Tier 4 Final/Stage IV) QSC

QSC8.3 QSC (Tier 3) QST30 (Tier 2) QSK23 (Tier 2)

QSK19 (Tier 2) QSK(Tier 2) QSM (Tier 2)

QSM (Tier 3) QSM11 QSNT

QSK19 QSX (Tier 2)

X Series:

X12 (2571) X12 (2571) X12 (Stage V) X15 (Stage V)

P Series:

Power Units-Stage V

Hot Selling Products

Our Company

Warehouse

Packing&Shipping

Certificate

Our Team

Customer Visiting

FAQ

Q: How about the warranty?

A: All goods have 1 year warranty.

Q: What about the delivery time?

A: Normally in 1 week.

Q: Other suppliers have a better price than yours?

A: To create the greatest benefit for clients is our belief, if you have a better price, please let we know.

We will try our best to meet your price and support your business.

Q: What about the shipment?

A: We can arrange shipment by DHL, FedEx, UPS, TNT, EMS with competitive price. Of course,

customers can also use their own freight forwarders.

Q: How about the terms of payment?

A: Generally through T/T, Paypal and Western Union also accept.

F

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Support |

|---|---|

| Warranty: | 1 Year |

| Type: | Idler Pulley |

| Application: | Construction Diesel Engine |

| Certification: | CE, CCC |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

How do idler pulleys contribute to the functioning of HVAC and conveyor systems?

Idler pulleys play a crucial role in the functioning of HVAC (Heating, Ventilation, and Air Conditioning) and conveyor systems. Here’s a detailed explanation of how idler pulleys contribute to the operation of these systems:

HVAC Systems:

In HVAC systems, idler pulleys are primarily used for power transmission and belt tensioning. Here are the key ways in which idler pulleys contribute to the functioning of HVAC systems:

1. Belt Routing and Tensioning:

Idler pulleys guide and support the belts used in HVAC systems, ensuring proper routing and tensioning. They help keep the belts in alignment with the driving and driven pulleys, preventing slippage and ensuring efficient power transmission. Idler pulleys maintain the necessary tension in the belts, which is crucial for optimal HVAC system operation.

2. Load Distribution:

Idler pulleys assist in distributing the load evenly across the HVAC system. By supporting the movement of belts, they help distribute the load and minimize stress on individual components. Proper load distribution ensures balanced wear and tear, prolonging the lifespan of the system.

3. Noise and Vibration Reduction:

Idler pulleys contribute to reducing noise and vibration in HVAC systems. They help dampen vibrations caused by belt operation, resulting in quieter and smoother system performance. Reduced noise and vibration levels enhance the comfort and usability of the HVAC system.

4. System Efficiency:

Efficient idler pulley operation improves the overall efficiency of HVAC systems. Well-designed idler pulleys with low friction and proper tensioning minimize power losses, ensuring optimal energy consumption. By reducing inefficiencies and maximizing energy conservation, idler pulleys contribute to improved HVAC system performance.

Conveyor Systems:

In conveyor systems, idler pulleys are essential for belt support, tensioning, and guiding. Here’s how idler pulleys contribute to the functioning of conveyor systems:

1. Belt Support:

Idler pulleys provide support to the conveyor belt, preventing sagging and maintaining its shape. They are strategically positioned along the belt path to support the weight of the conveyed material, ensuring smooth and reliable transportation. Proper belt support is crucial for preventing belt damage and ensuring efficient material handling.

2. Tensioning:

Idler pulleys are used for belt tensioning in conveyor systems. They help maintain the appropriate tension in the conveyor belt, ensuring proper engagement with the drive pulley and preventing slippage. Proper belt tensioning is critical for efficient power transmission and preventing material spillage or jamming.

3. Belt Guiding and Tracking:

Idler pulleys guide and track the conveyor belt, ensuring it stays aligned and centered. They are designed with grooves or cylindrical surfaces that match the shape of the conveyor belt, providing guidance and preventing lateral movement. By maintaining proper belt tracking, idler pulleys minimize belt misalignment, reducing the risk of damage and improving overall conveyor system performance.

4. Load Distribution:

Idler pulleys contribute to even load distribution in conveyor systems. By supporting the belt and load, they help distribute the weight evenly across the system, minimizing stress on individual components. Proper load distribution ensures reliable and efficient operation, preventing premature wear and component failure.

5. System Reliability:

Reliable idler pulley operation is crucial for the overall reliability of conveyor systems. Idler pulleys that are correctly sized, well-maintained, and properly lubricated contribute to the smooth and continuous operation of the system. They help minimize downtime, reduce the risk of belt slippage or jamming, and ensure the efficient movement of materials.

Overall, idler pulleys are essential components for the functioning of HVAC and conveyor systems. Their role in belt routing, tensioning, load distribution, noise reduction, system efficiency, and reliability makes them integral to the smooth operation and performance of these systems.

What role do idler pulleys play in maintaining proper belt alignment?

Idler pulleys play a crucial role in maintaining proper belt alignment in mechanical systems. Here’s a detailed explanation of the role idler pulleys play in maintaining proper belt alignment:

Proper belt alignment refers to the correct positioning of the belt along the pulleys in a system. It ensures that the belt remains centered on the pulleys and follows its intended path without deviating or slipping off. Belt misalignment can lead to a range of issues, including increased friction, wear, noise, and reduced power transmission efficiency. Idler pulleys help address these alignment challenges and contribute to the smooth operation of the system.

1. Belt Tracking:

Idler pulleys guide the belt and help maintain its tracking along the pulleys. They are strategically positioned to ensure that the belt remains in the desired position and follows the correct path. By providing a reference point and support, idler pulleys prevent the belt from wandering or shifting laterally, which could otherwise cause misalignment.

2. Tension Adjustment:

Idler pulleys can be used to adjust and maintain the tension in the belt, which is crucial for proper alignment. By adding or removing idler pulleys or adjusting their position, the tension in the belt can be controlled. Proper tension ensures that the belt remains engaged with the pulleys and does not slack or become too tight, both of which can lead to misalignment.

3. Belt Support:

Idler pulleys provide support to the belt, helping to prevent sagging or excessive vibration. They act as additional contact points along the belt’s path and distribute the load, ensuring that the belt remains in its intended position. This support helps maintain the alignment of the belt, especially in applications where the belt spans long distances or encounters varying loads.

4. Load Distribution:

Idler pulleys contribute to load distribution across the belt. By introducing additional pulleys strategically, the load on the belt can be divided, reducing stress on individual components. This helps to minimize the risk of belt misalignment due to uneven loading or excessive strain. By distributing the load, idler pulleys promote uniform wear and ensure the longevity of the belt.

5. Vibration and Noise Reduction:

Idler pulleys play a role in reducing vibration and noise in mechanical systems. Misaligned belts can cause excessive vibration and noise due to uneven forces and increased friction. By maintaining proper alignment, idler pulleys help minimize these issues, resulting in quieter operation and increased system stability.

Overall, idler pulleys are essential components in maintaining proper belt alignment. Their role in guiding the belt, adjusting tension, providing support, distributing load, and reducing vibration ensures that the belt remains properly aligned, leading to improved efficiency, reduced wear, and extended belt life in mechanical systems.

How does an idler pulley contribute to the proper tensioning of belts and chains?

An idler pulley plays a crucial role in maintaining proper tension in belts and chains within mechanical systems. Let’s explore how an idler pulley contributes to the proper tensioning:

1. Taking Up Slack:

When a belt or chain is installed in a system, there may be some initial slack or looseness. The idler pulley is strategically positioned to take up this slack by applying tension to the belt or chain. It helps to eliminate any excessive play and ensures that the belt or chain remains properly tensioned.

2. Compensation for Thermal Expansion and Wear:

Belts and chains can experience thermal expansion during operation due to changes in temperature. Additionally, over time, belts and chains may stretch or wear out. The presence of an idler pulley allows for compensation of these factors by providing an adjustable point of tension. The idler pulley can be adjusted to maintain the desired tension, compensating for any expansion or wear that may occur.

3. Preventing Belt or Chain Slippage:

If a belt or chain is not properly tensioned, it can slip or derail from the pulleys or sprockets it is meant to drive. This can lead to loss of power transmission, reduced efficiency, and potential damage to the system. The idler pulley applies the necessary tension to keep the belt or chain securely engaged with the other pulleys or sprockets, preventing slippage and ensuring reliable power transfer.

4. Maintaining Belt or Chain Alignment:

Proper alignment of belts and chains is essential for smooth operation and efficient power transmission. The idler pulley helps maintain alignment by guiding the belt or chain along the correct path and preventing it from wandering or deviating from the intended route. This contributes to reduced wear, noise, and vibration in the system.

5. Absorbing Shock and Reducing Vibrations:

An idler pulley can also help absorb shock and reduce vibrations within the belt or chain system. By providing a point of contact and tension, the idler pulley helps to dampen any sudden or excessive movements, resulting in smoother operation and reduced stress on the system components.

It’s important to note that the proper tensioning of belts and chains requires careful consideration of factors such as the manufacturer’s specifications, load requirements, and operating conditions. The idler pulley, along with other tensioning devices in the system, should be adjusted and maintained to ensure optimal performance and longevity of the belts and chains.

editor by CX

2024-05-17